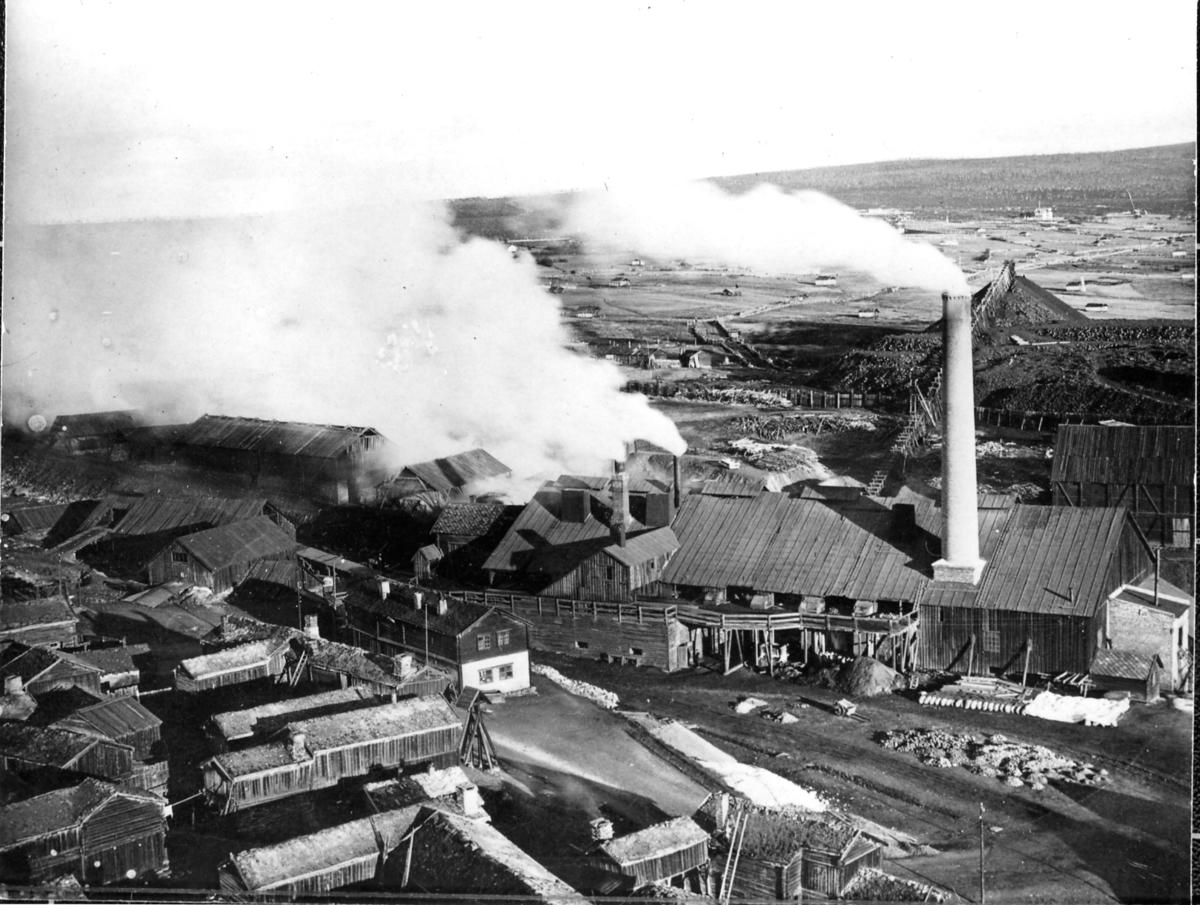

The smelter at Røros in 1907 Ole A. Aalen

Alexander Austnes

The smelting houses were the centre point of the works. A smelting works, with the smelting house as the central building, was made up of different works buildings, workshops, stores and administration buildings all collected around a smelting place or ore place and close to a river which was the main artery of the whole plant.

In choosing the place to build a smelting house there were several factors to consider. The starting point was the availability of copper ore, but access to large forests of timber and the availability of water power were also decisive in the production of copper.

Primarily it was important to find a situation that required the least amount of transport. Firstly, the ore had to be transported from the mines to the smelting house, which could be several kilometres away. Secondly, the operation of the smelters relied on the availability of charcoal and firewood.

Another deciding factor for the operation of the smelting plant was a stable supply of water-power. The smelting houses therefore had to be situated by a flowing river that did not freeze over in the winter months and had sufficient power to drive the bellows that forced air into the smelting furnaces.

The main smelting plant at Røros Copper Works was situated on the Hitter River, approximately 10 km. away from Storwartz where the mining community later grew up. Here the smelting house was working more or less continuously from 1646 until the Company dissolved in 1953. The slag heaps, that are so characteristic in Røros were produced by slag produced in the smelting house.

Only a few years after production commenced at Røros the surrounding forests were decimated over a large area. The cost of transporting charcoal and wood to the smelting house increased with the distance. Eventually it became both easier and less expensive to transport the ore to those places where there was access to charcoal and wood, so the Company therefore built several smaller smelting houses. In all, there were 12 additional, smaller smelting houses belonging to Røros Copper Works, which were in operation for shorter or longer periods.

From the 1880s the Company invested heavily in new technology and the modernisation of the production process and by the end of the 1800s Røros Copper Works was technically among the best mines in Europe. The smelting of copper was then centralised at the main plant situated in Røros and the activity at the other smelting houses discontinued. The last smelting house at Røros was built up again after a fire in 1888. Another fire damaged the smelting house in 1953, a fact, which contributed to the final end of smelting in Røros.

Again, in 1975 the smelting house caught fire and there were only bits and pieces left. The building was subsequently re-erected as a cultural heritage site and in 1988 it was taken over by the Røros Museum